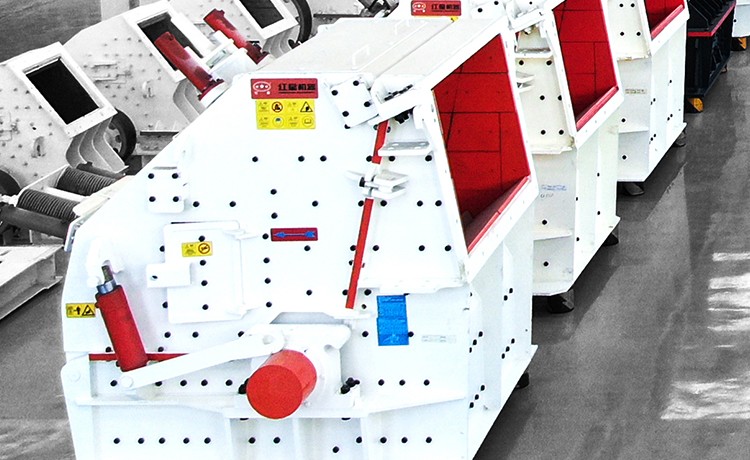

CI series of new type impact crusher integrates the current domestic and international advanced impact crusher technology, the rotor and crushing cavity are refined design for different applications, and a large number of new high wear-resistant materials are used, which are greatly improved the performance and processing capacity of the equipment . It exhibits excellent crushing effect in applications of industries such as medium hardness and low abrasive quarrying and gravel, cement, concrete and asphalt recycling, slag recycling etc.

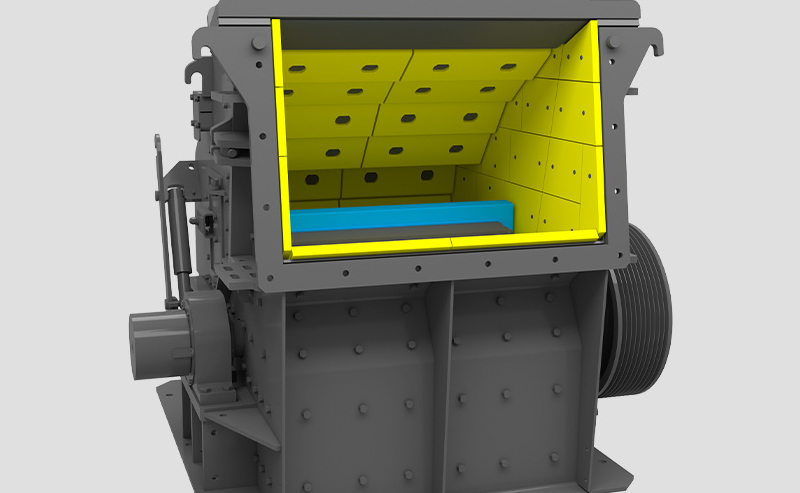

The precise design of the rotor and cavity type, speed and power are reasonably matched to meet the different applications of coarse crushing, medium and fine crushing and material recovery;

The sturdy heavy-duty rotor structure improves the equipment handling capacity and crushing ratio; the high-quality welding structure ensures that the machine can withstand the maximum impact and obtain a good crushing effect;

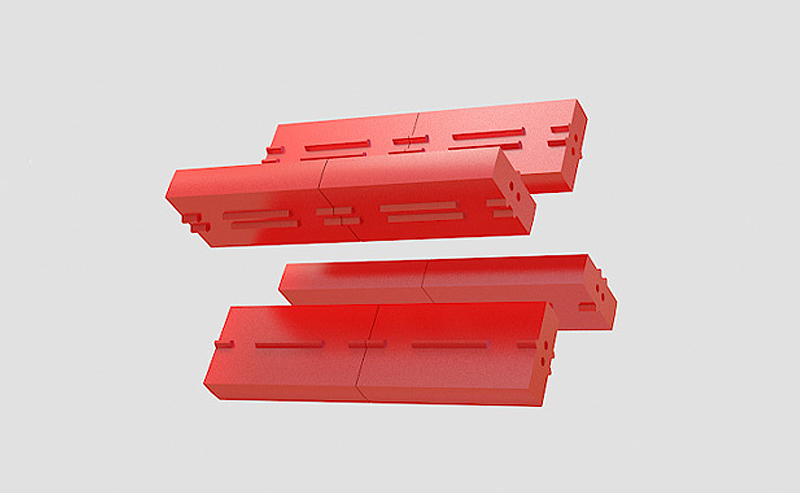

The ship plate hammer, firm locking structure, has a good impact resistance, anti-wear properties and maintain a stable discharge particle size;

The unique shape of the blow bar and the firm locking structure make the blow bar have good impact resistance and abrasion resistance and maintain a stable discharge particle size.

The hydraulic adjustment device has the function of automatic overload protection, which can quickly complete the replacement of wear parts and control the discharge granularity and gradation of the equipment.

The modular design makes most of the wearing parts interchangeable, effectively reducing the consumption of wearing parts, extending the replacement cycle and saving costs.

Technical Specifications

| Model | Maximum Feeding Size (mm) | Capacity(t/h) |

| CI1110 | 250 | 60-210 |

| CI1213 | 300 | 80-280 |

| CI1316 | 300 | 100-350 |

| Cl1321 | 300 | 130-430 |

| Cl1521 | 350 | 200-600 |

| Cl1524 | 350 | 240-700 |

| Cl1630 | 400 | 300-900 |

| Model | Maximum Feeding Size (mm) | Capacity(t/h) |

| CI1313 | 600 | 100-480 |

| CI1415 | 600 | 120-600 |

| CI1620 | 800 | 220-900 |

| CI2023 | 800 | 200-2000 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.