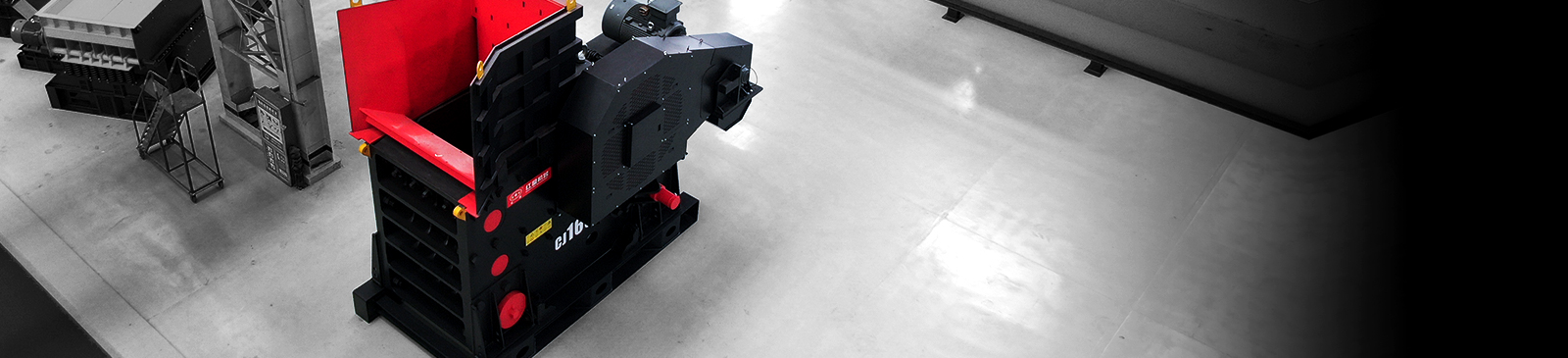

The CJ series jaw crusher is with excellent performance introduced by Hongxing Heavy Industry Machinery Co., Ltd. based on the needs of customers. Different from the traditional jaw crusher, there are significant improvements in the crusher's motion parameters, structural forms, and adjustment methods.

The CJ series jaw crusher commonly used for primary or secondary crushing in the mining material crushing. It has less occupied space, larger crushing ratio and more stable operation. It has more advantages in transportation, installation, maintenance and adjustment. Particularly suitable for fixed crushing lines and mobile crushing plants.

Excellent feeding ability -The deep V cavity allows the material into the crushing cavity without any obstruction, thus ensuring the best feeding ability.

Reliable equipment operation- Greater fatigue resistance, higher reliability, and longer service life provide a good operating environment for the equipment.

High yield and big crushing ratio- Large crushing ratio and stable operation, which fully guarantees the high yield and high efficiency of the crushing operation.

The side plate of the frame, the front wall and the rear beam are connected by cylindrical pin positioning and high-strength bolts, which avoids the defects that the welding frame is easy to cause stress concentration;

The integral motor frame makes the installation more easier; reduces the installation space; Crusher and the integral motor bracket move synchronously, which improves the load on the V-belt.

Technical Specifications

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Maximum Feeding size(mm) | Capacity(t/h) |

| CJ80 | 410 | 55-335 |

| CJ96 | 480 | 105-390 |

| CJ100 | 600 | 150-420 |

| CJ106 | 560 | 150-500 |

| CJ116 | 608 | 165-580 |

| CJ120 | 700 | 175-610 |

| CJ125 | 760 | 270-831 |

| CJ130 | 800 | 270-831 |

| CJ150 | 960 | 340-880 |

| CJ160 | 960 | 430-1145 |

| CJ180 | 960 | 500-1300 |

| CJ200 | 1200 | 630-1435 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

CI Series Impact Crusher

Cl series impact crusher is a crushing equipment developed by integrating excellent scientific research technology at home and abroad.

READ MORE

CI Series Impact Crusher

Cl series impact crusher is a crushing equipment developed by integrating excellent scientific research technology at home and abroad.

READ MORE

HCG Series Gyratory Crusher

HCG Series Gyratory Crusher is a new type of high-efficiency coarse crushing equipment independently developed by HXZG Group based on the introduction of advanced technology from Europe and the United States and the development needs of modern industry, aiming at the specific needs of large equipment in the global market.

READ MORE

HCG Series Gyratory Crusher

HCG Series Gyratory Crusher is a new type of high-efficiency coarse crushing equipment independently developed by HXZG Group based on the introduction of advanced technology from Europe and the United States and the development needs of modern industry, aiming at the specific needs of large equipment in the global market.

READ MORE