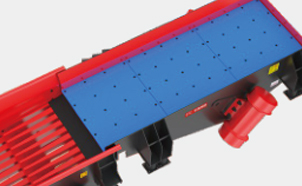

HST series feeding and pre-screening combination machine is composed of independent operation of plate feeder and grizzly screen, plate feeder precisely control the feeding amount, grizzly screen and feeder separate operation, not affected by the feeder frequency, can be set separately stroke size and speed, so as to provide better screening effect. It is widely used in quarry, mining, building materials, electric power, coal and chemical industries, suitable for high content of fine material feeding and pre-screening of raw materials.

Feeding and screening units operate independently, Flexible adjustment of frequency;

To solve the problem of raw material stickiness, and feeding with much soil content.

Reduce the coarse crushing load after pre-screening, Increase the capacity of the whole line.

Flat feeder

Bar screen for pre-treatment

Technical Specifications

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Feeding width (mm) |

Screen width (mm) |

Processing capacity (t/h) |

| HST0863 | 690 | 750 | 75-240 |

| HST1063 | 950 | 1020 | 90-300 |

| HST1263 | 1080 | 1150 | 120-400 |

| HST1363 | 1230 | 1300 | 165-550 |

| HST1673H | 1500 | 1600 | 240-800 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.