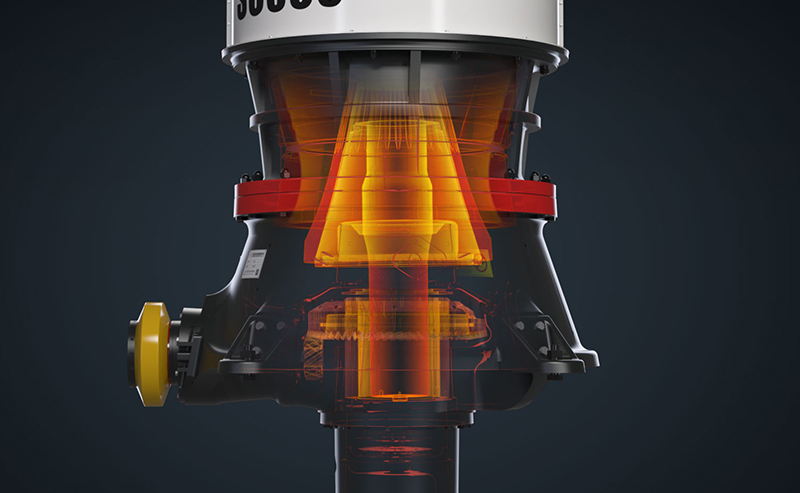

SC series cone crusher is developed on the basis of absorbing the world's most advanced technology and integrating the company's many years of design experience. It integrates mechanical, hydraulic, electrical and intelligent control and remote control. It has the advantages of high efficiency, good grain shape, hydraulic adjustment, remote automatic control, choice of multiple crushing cavity types, and adjustment of eccentricity without changing any parts.

SSC series cone crusher can be used as the second-stage crushing equipment to match with jaw crusher or gyratory crusher, or as the third-stage or fourth-stage crushing equipment, which can meet most production needs of users.

The new crusher structure, optimized laminated crushing cavity type, intelligent automatic control system and innovative Internet control system make the SC(S) series single-cylinder hydraulic cone crusher.

In the whole lining wear life cycle, the discharge particle size and productivity remain basically unchanged.

Effectively prevent dust and other sundries from entering the equipment and oil tank to avoid lubricating oil pollution.

The human- machine interaction interface is easy to understand, easy to use and efficient, making the operation and maintenance simple, maximize productivity.

Using super high alloy manganese steel (ZGMn18Cr2), Long service life, no need for packing, easy replacement.

Gear Using spiral bevel gear design, High carrying capacity, stable power transmission and low noise.

Sliding bearing The sliding bearing is made of lead bronze and special oil wedge design to prevent bearing damage.

Technical Specifications

SC Single Cylinder Cone Crusher Medium Crushing Series

SC Single Cylinder Cone Crusher Fine Crushing Series

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

SC Single Cylinder Cone Crusher Medium Crushing Series

| Model | Cavities | Feeding Size (mm) |

Capacity (t/h) |

| SC100S | C1 | 240 | 85-170 |

| C2 | 200 | 70-130 | |

| SC160S | C1 | 360 | 125-345 |

| C2 | 300 | 108-305 | |

| SC250S | C1 | 450 | 265-524 |

| C2 | 400 | 225-448 | |

| SC315S | C1 | 560 | 349-1050 |

| C2 | 500 | 318-892 | |

| SC450S | C1 | 600 | 498-1500 |

| C2 | 480 | 454-1274 |

SC Single Cylinder Cone Crusher Fine Crushing Series

| Model | Cavities | Feeding Size (mm) |

Capacity (t/h) |

| SC100 | F1 | 150 | 45-135 |

| F2 | 90 | 43-118 | |

| F3 | 50 | 25-40 | |

| SC160 | F1 | 200 | 69-215 |

| F2 | 115 | 57-184 | |

| F3 | 75 | 70-90 | |

| SC250 | F1 | 240 | 116-396 |

| F2 | 140 | 97-346 | |

| F3 | 70 | 90-251 | |

| SC315 | F1 | 275 | 177-662 |

| F2 | 215 | 209-643 | |

| F3 | 175 | 162-552 | |

| F4 | 85 | 175-325 | |

| SC560 | F1 | 300 | 448-1512 |

| F2 | 195 | 380-1373 | |

| F3 | 90 | 357-912 | |

| SC750 | F1 | 370 | 394-2181 |

| F2 | 300 | 342-2020 | |

| F3 | 230 | 267-1814 | |

| F4 | 120 | 248-1165 | |

| F5 | 85 | 185-1170 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.