HX series lubricated vibrating screen is suitable for various screening operations such as heavy, medium and fine screening. This screening machine is an ideal equipment for processing the products after primary crushing and secondary crushing. It can also be used for inspection screening in the process and final product screening.

HX series lubricated vibrating screen have a vibration intensity of up to 4.5G. Fully meet the requirements of the stone industry,and is more conducive to the application of viscous and moist materials. In terms of sealing and environmental protection, the HX series is also fully prepared, and can quickly install dust-proof systems and sprinkler systems according to your requirements at any time.

Finite element dynamic analysis, scientific control

All series of high-strength plates to ensure the life

Special torque wrench to ensure the reliability of the connection

High standard HUCK ring groove rivet connection, good anti-loosening effect

The vibration intensity of HX series vibrating screen is as high as 4.5G

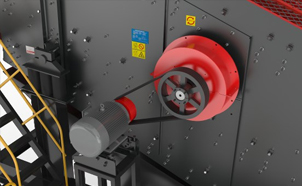

The compact structure of the pulley drive system is installed with a taper sleeve, and the motor wheel can be quickly replaced to change the equipment speed.

In response to increasingly stringent environmental protection requirements, all HX series vibrating screens can be equipped with a sealed dust-proof system and a pipeline spray system.

Technical Specifications

| Model | Sieve Layer | Sieve Obliquity (°) |

Motor Power (kw) |

Vibrating Frequency (r/min) |

Max.Feeding Size (mm) |

Capacity (t/h) |

Dimensions(mm) (L×W×H) |

| 2HX1545 | 2 | 18 | 15 | 780-900 | 200 | 45-500 | 5380×2295×1410 |

| 3HX1545 | 3 | 18 | 18.5 | 780-900 | 200 | 55-500 | 5575×2295×1990 |

| 4HX1545 | 4 | 18-20 | 22 | 780-900 | 200 | 65-500 | 5765×2295×1990 |

| 2HX1855 | 2 | 18 | 18.5 | 780-900 | 200 | 55-600 | 5680×2565×1450 |

| 3HX1855 | 3 | 18 | 22 | 780-900 | 200 | 65-600 | 5900×2565×2110 |

| 4HX1855 | 4 | 18-23 | 22 | 780-900 | 200 | 75-600 | 6030×2565×2500 |

| 2HX2165 | 2 | 18 | 30 | 780-900 | 200 | 65-700 | 7160×2990×1690 |

| 3HX2165 | 3 | 18 | 30 | 780-900 | 200 | 75-700 | 7380×2990×2365 |

| 4HX2165 | 4 | 18-23 | 37 | 780-900 | 200 | 85-700 | 7430×2990×2500 |

| 2HX2465 | 2 | 18 | 37 | 780-900 | 200 | 80-800 | 7160×3290×1690 |

| 3HX2465 | 3 | 18 | 37 | 780-900 | 200 | 90-800 | 7380×3290×2365 |

| 4HX2465 | 4 | 18-23 | 37 | 780-900 | 200 | 100-800 | 7430×3290×2500 |

| 2HX2765 | 2 | 18 | 37 | 780-900 | 200 | 100-900 | 7180×3570×1805 |

| 3HX2765 | 3 | 18 | 45 | 780-900 | 200 | 110-900 | 7390×3570×2445 |

| 4HX2765 | 4 | 18-23 | 45 | 780-900 | 200 | 120-900 | 7480×3570×2715 |

| 2HX3065 | 2 | 18 | 37 | 780-900 | 200 | 110-1200 | 7180×3870×1805 |

| 3HX3065 | 3 | 18 | 45 | 780-900 | 200 | 120-1200 | 7390×3870×2445 |

| 4HX3065 | 4 | 18-23 | 45 | 780-900 | 200 | 130-1200 | 7480×3870×2715 |

| 2HX3075 | 2 | 18 | 22×2 | 780-900 | 300 | 120-1300 | 8700×4055×1980 |

| 3HX3075 | 3 | 18 | 37×2 | 780-900 | 300 | 130-1300 | 8940×4120×2720 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Max.Feeding Size (mm) | Processing capacity(t/h) |

| 2HX1545 | 200 | 45-500 |

| 3HX1545 | 200 | 55-500 |

| 4HX1545 | 200 | 65-500 |

| 2HX1855 | 200 | 55-600 |

| 3HX1855 | 200 | 65-600 |

| 4HX1855 | 200 | 75-600 |

| 2HX2165 | 200 | 65-700 |

| 3HX2165 | 200 | 75-700 |

| 4HX2165 | 200 | 85-700 |

| 2HX2465 | 200 | 80-800 |

| 3HX2465 | 200 | 90-800 |

| 4HX2465 | 200 | 100-800 |

| 2HX2765 | 200 | 100-900 |

| 3HX2765 | 200 | 110-900 |

| 4HX2765 | 200 | 120-900 |

| 2HX3065 | 200 | 110-1200 |

| 3HX3065 | 200 | 120-1200 |

| 4HX3065 | 200 | 130-1200 |

| 2HX3075 | 300 | 120-1300 |

| 3HX3075 | 300 | 130-1300 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

LS Series ™ Linear Vibrating Screen

The equipment is suitable for the fine screening of finished products and crushed rocks in the closed-circuit crushing process, dewatering, etc.

READ MORE

LS Series ™ Linear Vibrating Screen

The equipment is suitable for the fine screening of finished products and crushed rocks in the closed-circuit crushing process, dewatering, etc.

READ MORE

HX-D ™ Heavy Duty Double Shaft Circular Vibrating Screen

The HX-D heavy-duty double-shaft circular vibrating screen has a stronger structure than the HX series, so it can screen materials with larger particle sizes.

READ MORE

HX-D ™ Heavy Duty Double Shaft Circular Vibrating Screen

The HX-D heavy-duty double-shaft circular vibrating screen has a stronger structure than the HX series, so it can screen materials with larger particle sizes.

READ MORE

Product Name

You Name

Your Phone or Whatsapp

You Email*

Message

HPM ™ Multi Cylinder Hydraulic Cone Crusher SC ™ Single Cylinder Hydraulic Cone Crusher CJ Series ™ Euro Jaw Crusher HCG Series ™ Gyratory Crusher CI Series ™ Impact Crusher MP series™ Modular Production Line HX ™ Thin Oil Vibrating Screen HX-D ™ Heavy Duty Double Shaft Circular Vibrating Screen LS Series ™ Linear Vibrating Screen HSF Series ™ Vibrating Feeding Equipment HST Series ™ Combined Vibrating Feeder VSI-A7 ™ Series Impact Sand Maker With Deep Cavity MTF ™ Wheeled Mobile Crushing Station WT ™ Crawler-type Mobile Crushing Station